It was a slow day. We realized early on that Take Two’s hull was over 1.5 inches thick and the 2.5” thru-hulls we had weren’t going to work. It looked like we were going to have to buy the extra long ones and cut them down. Of course, West Marine had nothing in stock. So we had to postpone a day while new thru-hulls are shipped in, which probably means doing the thru-hulls after the engines are put in the boat.

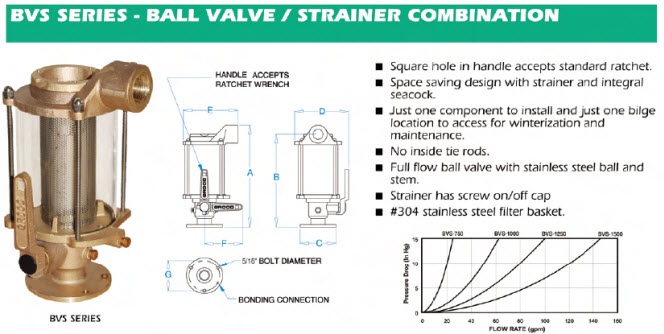

We did make some design decisions. Placement of the generator thru-hull has been very challenging. How to minimize the hose run, from the maximum depth, with the fewest elbows, and use a strainer that is easy to clean? I think this design is going to fit the bill.

It eliminates any plumbing between the ball valve and the strainer, particularly any bends where something would be likely to get stuck. It seems more likely that anything that gets sucked up (like little fishes) could swim or fall out when the suction stops. And the whole thing fits nicely down in the bilge, saving valuable space.

We also made some progress on the engine exhaust design. Our exhaust ports are very close to the waterline and there is the potential that waves could fill the exhaust system and flood the engine. Not wanting to rely solely on a rubber flapper to keep the water out, and also wanting to reduce “sneezing” from the exhaust, we’re prototyping a surge chamber to go just inboard of the exhaust ports.

It rained all afternoon, so not much else got done. I did finish running the new engine wire harnesses.